Learning Objective

Good Manufacturing Practice (GMP) for medicinal products relies on documentation. Good Documentation Practice (GDocP) is that part of GMP that applies to the creation, maintenance, use, and retention of documents to provide assurance of the quality of products.

In this module, we emphasise the crucial importance of GDocP and we identify five principles that underpin it. We explain the functions of the various types of documents that are used and discuss how they should be created and controlled. Finally, we set out requirements for record keeping – how data are to be entered into records, corrected if necessary, and how records must be retained.

Who will benefit from this module?

Everyone who works in a manufacturing environment in the pharma/biotech industry will benefit from this module. It will be of especial interest to quality assurance staff.

Learning Objectives

- Explain why Good Documentation Practice is important, and identify principles that underpin it

- List the various types of documents used and explain their functions

- Discuss how documents should be created and controlled

- Specify requirements for record keeping, including those for entering and correcting data

Module Outline

Module overview - An outline of the module’s scope and objectives, and notes on terminology.

Importance and principles of GDocP - Good Documentation Practice underpins Good Manufacturing Practice. In this session we emphasise the crucial importance of compliance with, and we identify fundamental principles of GDocP.

Types of documents - In this session we describe the various types of documents found in a GMP-compliant environment – their functions, contents, and relationships.

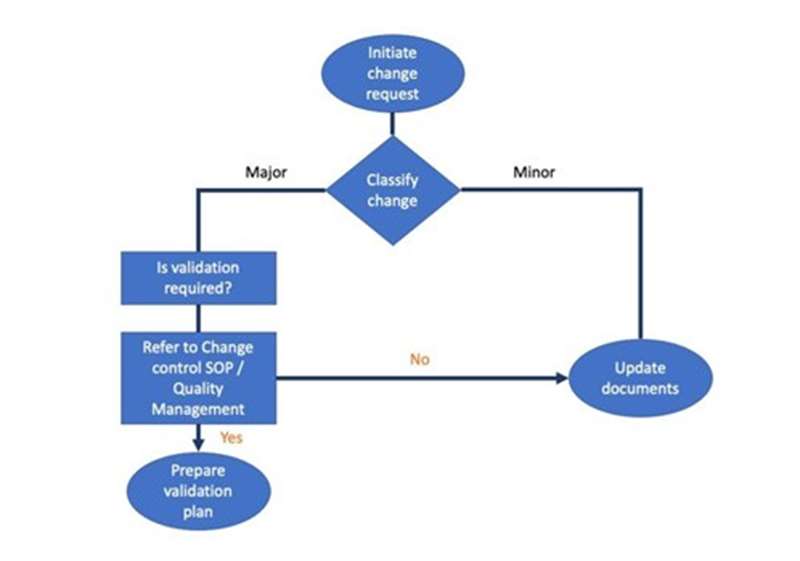

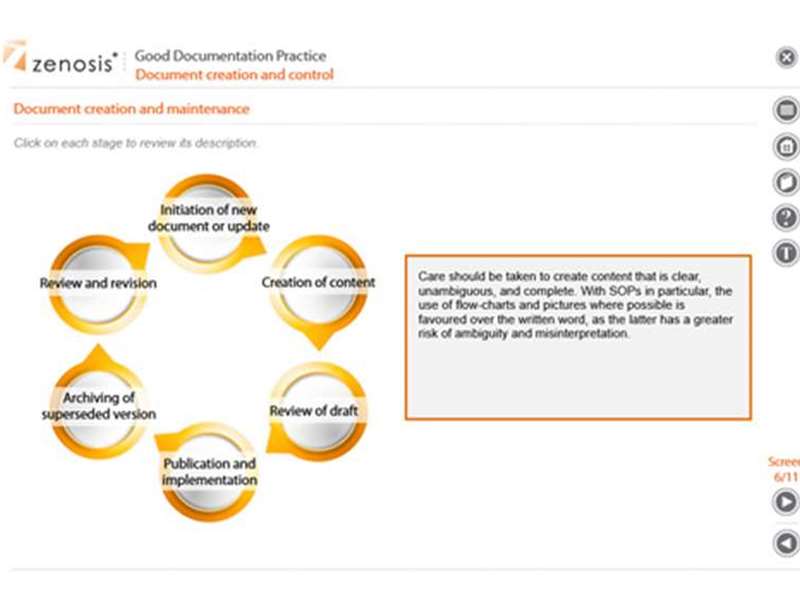

Document creation and control - Careful control of GMP-relevant documentation is vitally important for quality management. In this session we identify principles of document control and characteristics of controlled documents, outline how documents should be created and maintained, and give advice on good practice in the creation of templates or masters for records.

Record keeping - Scrupulous and thorough recording of manufacturing activities is very important for a variety of reasons. In this session we set out these reasons, we provide rules for recording and correcting data in compliance with GMP requirements, and we specify requirements for the retention of records.

Assessment - Multiple-choice mastery assessment.